CTP PO 603 (Conti Bake BE 6570 alternative)

CTP PO 603 (Conti Bake BE 6570 alternative)

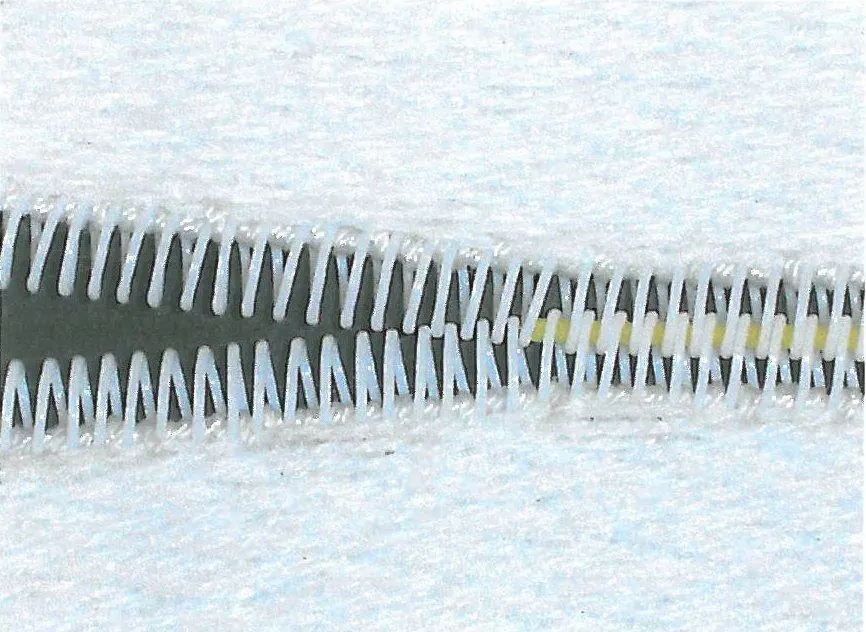

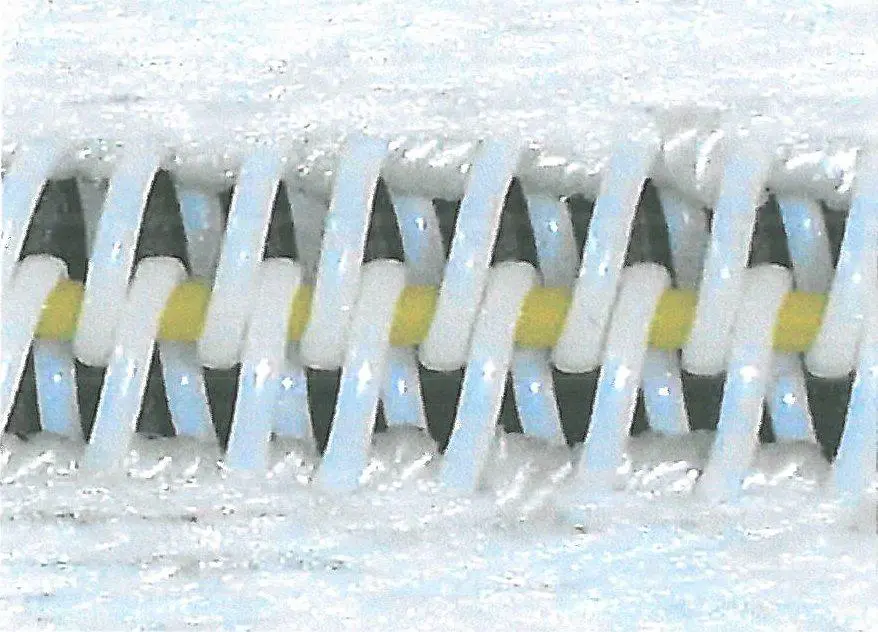

Baking belts with woven in polyester spiral SS52

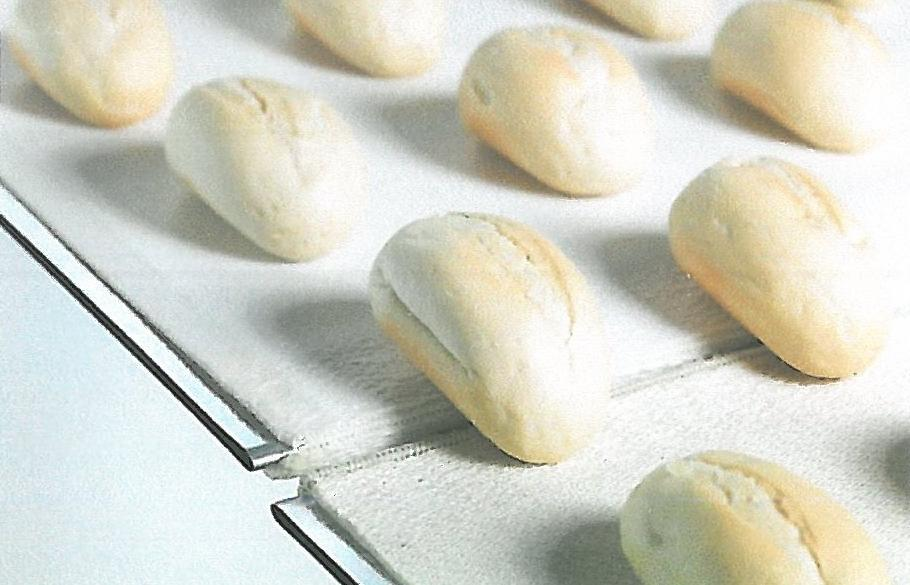

We would like to introduce you to the CTP PO 603 baking belt, which caused a great stir when it was launched on the market and became a huge hit. Used in many bakery devices, e.g. in proofers and in various types of dough transport machines.

Among the properties that will interest you in the first place, we can mention:

- fully synthetic, very resistant fabric – guaranteeing long life;

- strong weft with monofilament yarn ensuring high lateral stability;

- high stability of the belt ensures perfect adhesion and resistance to stretching;

- easy to control and ideal gliding conditions;

- very high flexibility of the fabric itself, as well as connections finished with a polyester spiral type SS52, allowing to overcome knife rollers with a diameter of 6 mm;

- high air permeability;

- easy to clean.

The most important features:

- polyester belt;

- standard weight 1500 g/m2;

- thickness 2.2mm;

- manufactured in accordance with FDA approval for contact with unpackaged food;

- breaking strength 144 kN/cm;

- coefficient of friction on stainless steel 0.15;

- non-stick surface of the carrier side;

- resistance to constant temperature of 140 °C, temporary temperature up to 220 °C;

- mildew resistant.

Usage:

- baking tunnels;

- conveyors equipped with knife rollers;

- dough shaping and kneading process;

- storage systems;

- loading into furnaces.

The CTP PO 603 belt can be used wherever the dough is wet or dry and has to travel a long distance or stays on the belt for a long time and finally has to overcome a small knife roller. It is the ideal solution for fast belt installation and low equipment downtime. The SS52 spiral is made entirely of PE, which positively affects the characteristics of the belt rewinding and excludes the contact of dough or pastries with metal.

The CTP PO 603 belt performs much better than felt belts, which must be replaced regularly due to dirt, lack of straight glide, stretching or transverse shrinkage.

Technical data:

Type: | |

| Belt construction: | Carrying side: 100% polyester, multi-layered, with a felt-like surface, non-sticking, air permeability 1000 m³/h at 10mmWS Bottom side: 100% polyester, single layer, coefficient of friction 0.15 after steel |

| Color: | white |

| Thickness: | 2.2mm |

| Libra: | approx. 1500 gsm |

| Width: | up to 2000 mm without additional longitudinal connections |

| Breaking strength: | 166 kg/cm |

| Tensile strength: | for 1% stretch 5 kg/cm width |

| Minimum Roll Diameter: | 6mm |

| Temperature resistance: | continuous 140ºC, temporary 220ºC |

| Chemical properties: | resistant to water, moisture, oils, vegetable and animal fats |

| Connections: | woven in polyester spiral |

Connection types:

Woven polyester helix available in different types:

- SS52 – standard (for rollers from 6 mm in diameter);

- SS52 PEEK (temperature resistant up to 300ºC).